Unwinding creel

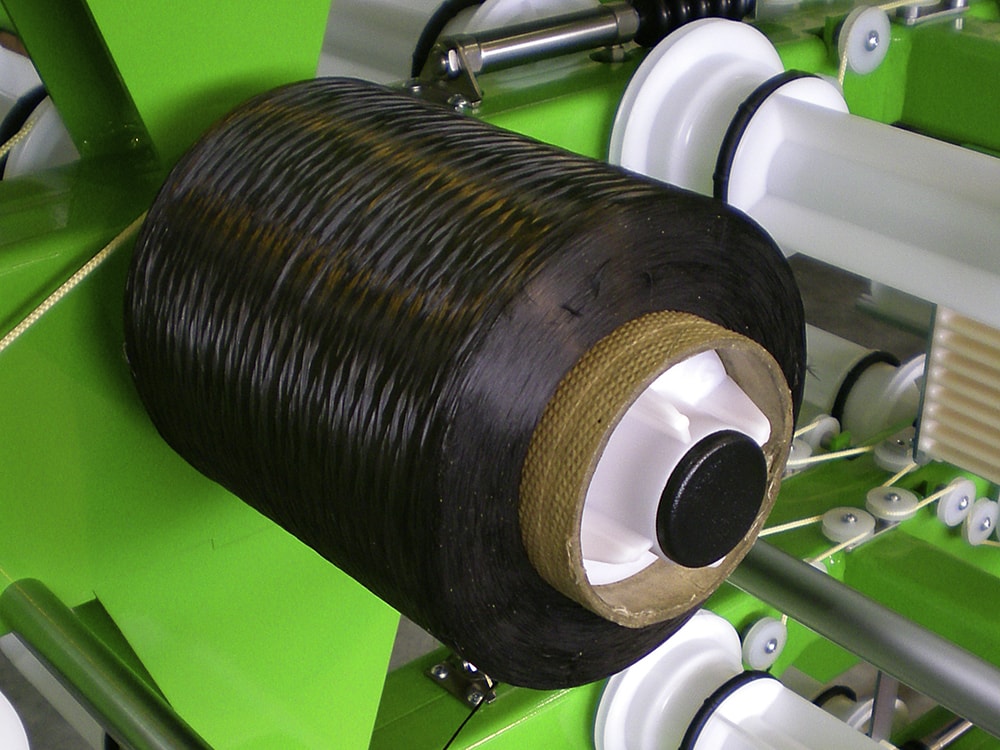

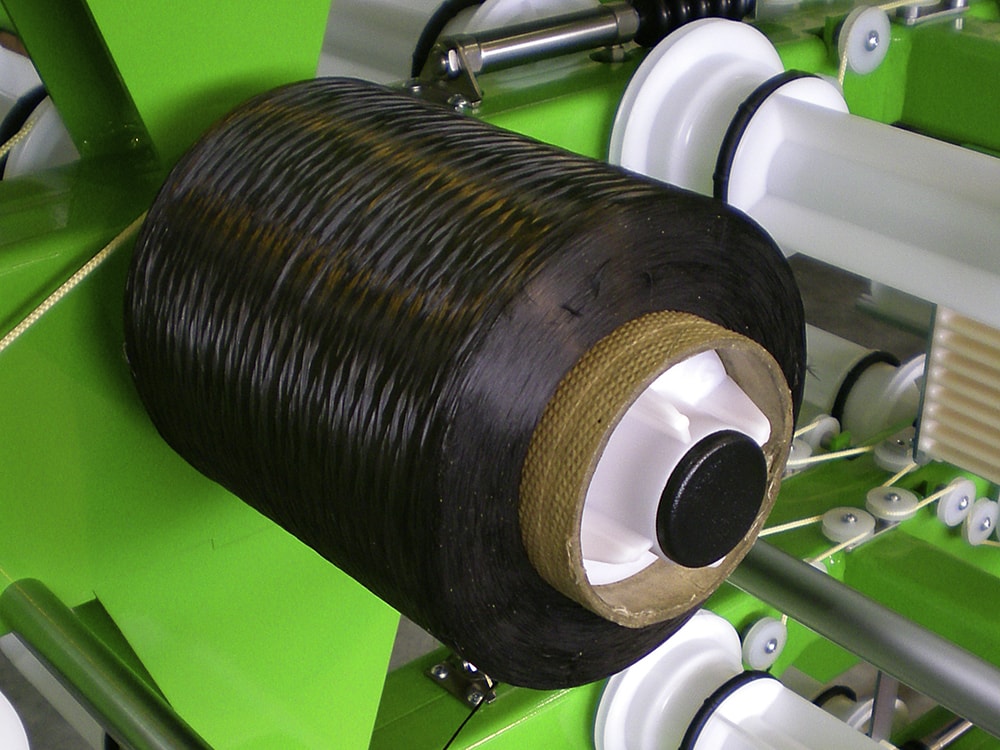

Thanks to its rugged design, each standard unit may support 96 or 192 of a diameter of 200 mm and a length of 290 mm with a 3" inside diameter core.

Each unit is mounted on rollers thus allowing for the spool feeding outside the working space and the free creel dimensioning depending on your needs (here 1,152 spools).

Each unit is mounted on rollers thus allowing for the spool feeding outside the working space and the free creel dimensioning depending on your needs (here 1,152 spools).

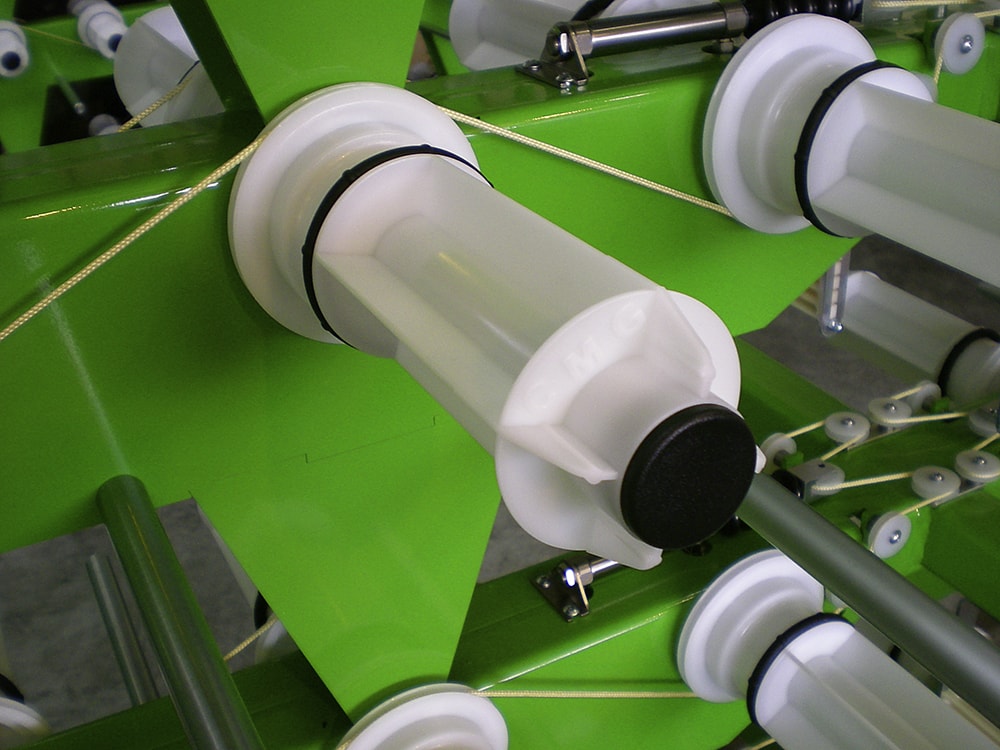

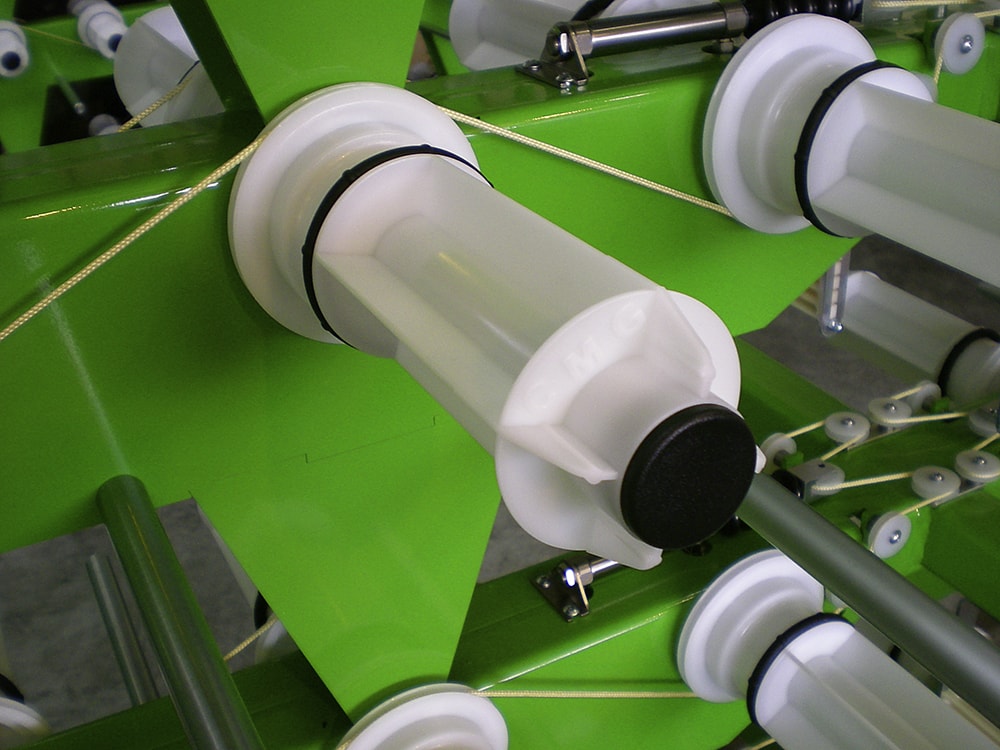

Our 3’’ package holders are mounted on bearings for effortless unwinding.

Our 3’’ package holders are mounted on bearings for effortless unwinding.

If needed, a braking tension may be applied to the whole creel thanks to a pneumatic cylinder.

If needed, a braking tension may be applied to the whole creel thanks to a pneumatic cylinder.

Thanks to tangential unwinding and the yarn passing through the spreader grid, it is unwound over the whole spool width without getting into touch with the other yarns. The yarn is then guided through ceramic eyelets until reaching your machine.

Thanks to tangential unwinding and the yarn passing through the spreader grid, it is unwound over the whole spool width without getting into touch with the other yarns. The yarn is then guided through ceramic eyelets until reaching your machine.

Chromium-plated guide rollers may be installed on the frame, so as to prevent the yarn from getting into touch with the upstream spool, if the latter has a bigger diameter.

Chromium-plated guide rollers may be installed on the frame, so as to prevent the yarn from getting into touch with the upstream spool, if the latter has a bigger diameter.

Examples of realizations

<< Download our leaflet

<< Download our leaflet

Thanks to tangential unwinding and the yarn passing through the spreader grid, it is unwound over the whole spool width without getting into touch with the other yarns. The yarn is then guided through ceramic eyelets until reaching your machine.

Thanks to tangential unwinding and the yarn passing through the spreader grid, it is unwound over the whole spool width without getting into touch with the other yarns. The yarn is then guided through ceramic eyelets until reaching your machine.